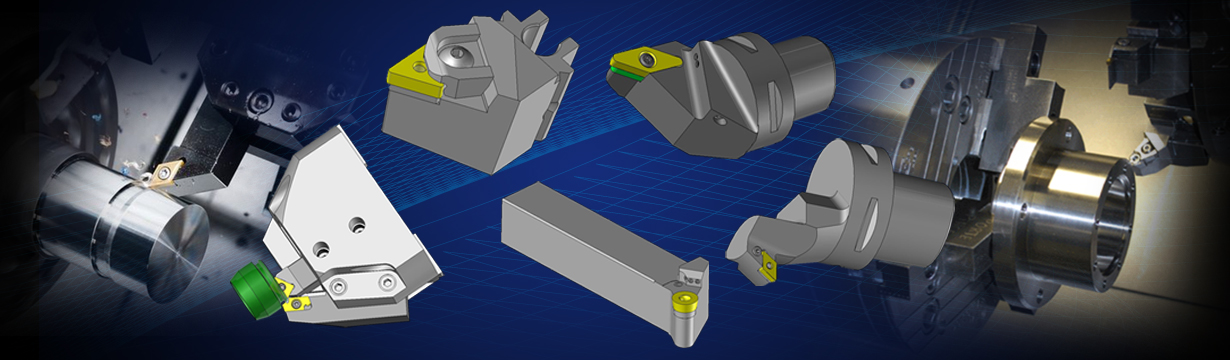

Différents types de Tournage

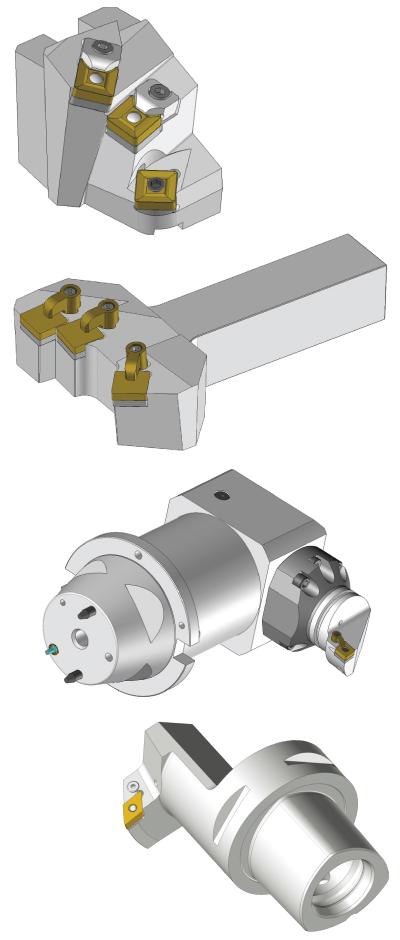

Tournage Extérieur et Intérieur

evatec-tools propose une large gamme d'outils pour le tournage extérieur et intérieur permettant de répondre aux opérations de chariotage, de profilage et de dressage:

- Porte-outils

- Angle d'attaque

- Buse d'arrosage standard ou HP

- Type de plaquette (nuances et géométrie)

Nos techniciens sont en mesure de vous conseiller sur le système de bridage de la plaquette dans le porte-outils et cela, en fonction du type d'opération à réaliser et de la taille de la pièce. Le but est que le contrôle des copeaux et l'état de surface de surface soient optimums. Le choix du bon outil permettra d'éviter la formation de bavures et les vibrations.

Pour les pièces de grandes dimensions demandant beaucoup de robustesse, des porte-outils à plaquettes négatives sont conseillés. Pour des matières collantes avec évacuation délicate des copeaux, des géométries positives sont disponibles.

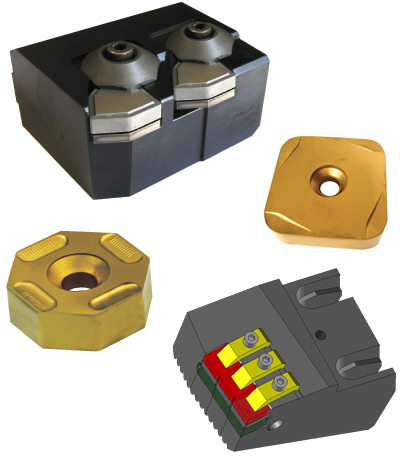

Tournage Lourd

Ce type de tournage implique l'usinage de pièces de grandes dimensions sur des machines robustes et puissantes nécessitant d'importants enlèvements de copeaux, sur des surfaces irrégulières, avec des profondeurs de coupe importantes, variables et pouvant atteindre 20 mm.

Pour sécuriser le process et pour contrôler les copeaux, evatec-tools propose des géométries étudiées, associées à des nuances tenaces résistantes à l'échauffement, permettant de réduire les arrêts machines et d'obtenir un excellent état de surface.

Tournage Dur

L'usinage de pièces en matériau dur, comme les aciers d'une dureté de 55-65 HRC, s'effectue encore bien souvent par rectification. Le tournage dur, associé à des géométries de coupe et nuances adaptées permet de réduire les temps d'usinage.

Le tournage dur est caractérisé par de faibles profondeurs de coupe et d'avance et par d'importants efforts spécifiques de coupe. Il apparaît de très hautes températures en cours de travail (entre 500° et 1500° selon les cas) à l'interface de l'arête de coupe et de la pièce.

Le développement, et l'amélioration de différents matériaux de coupe comme la céramique, le CBN et les carbures micrograins permettent la substitution du processus de rectification par l'usinage de matières dures avec des géométries de coupe définies. Ainsi en tournage on utilise avant tout des céramiques et du CBN alors qu'en perçage ou en fraisage on utilise également des outils en carbure monobloc à structure micrograins.