Applications et Matériaux Usinés

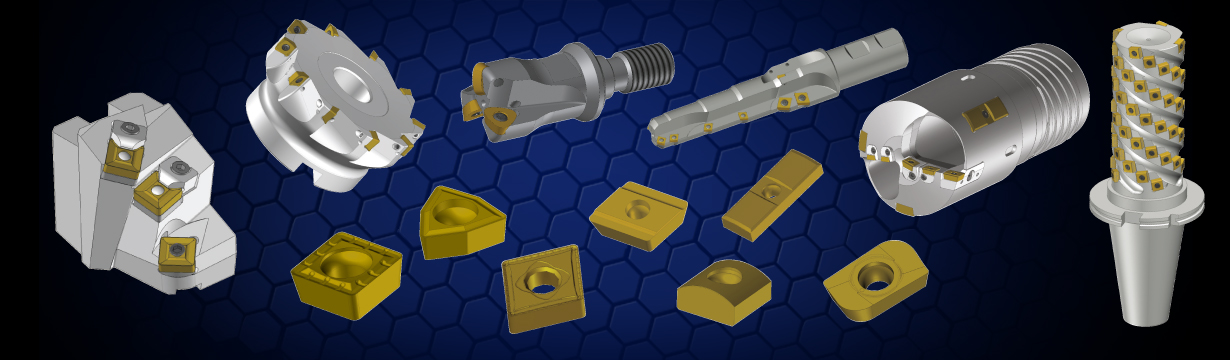

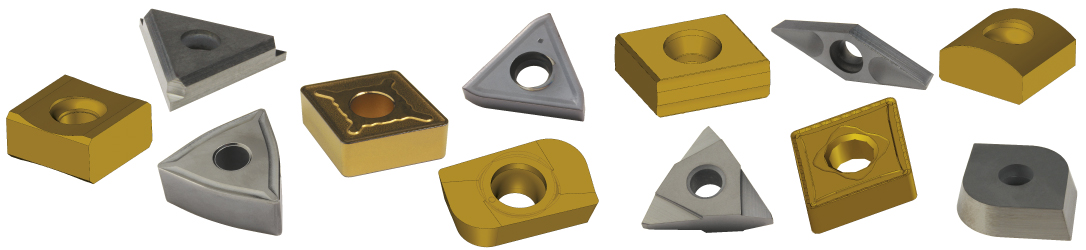

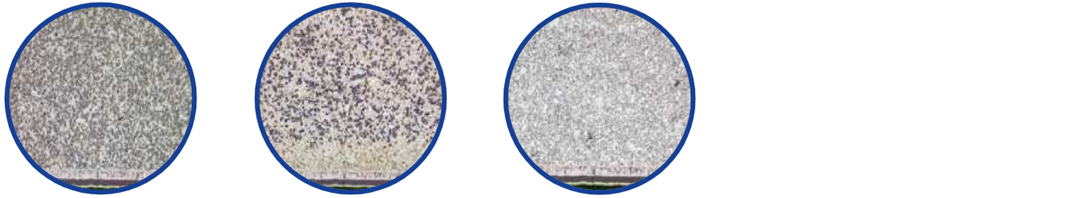

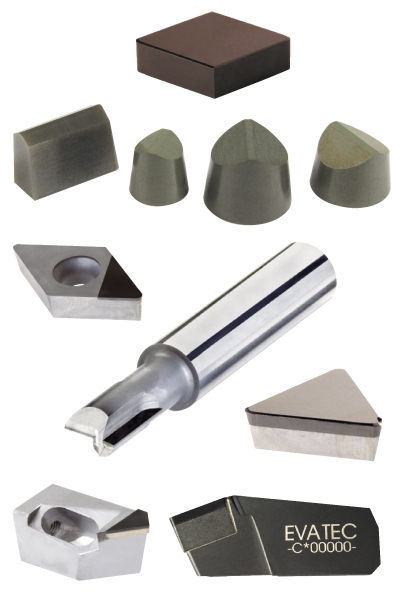

evatec-tools fabrique, en petites et grandes séries, des plaquettes de coupe en carbure, céramique, PCD et CBN, qu'elles soient standards ou spécifiques.

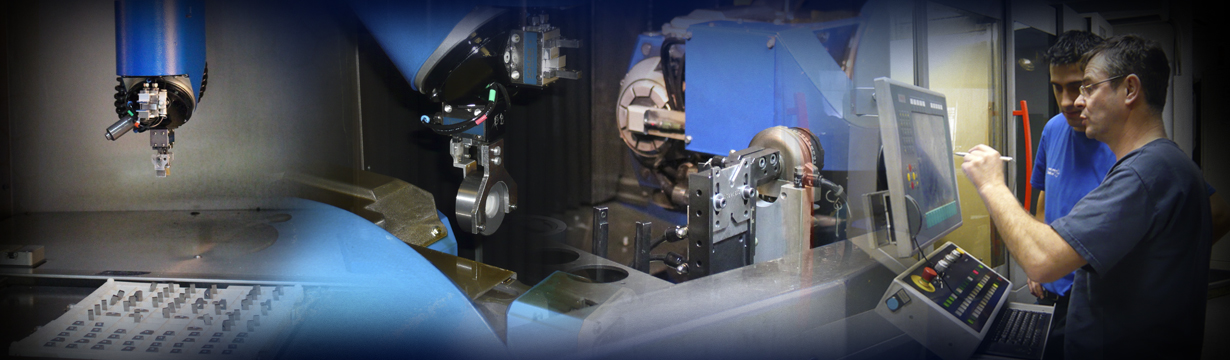

Bureaux d'études et des méthodes mettent à l'honneur le savoir-faire du groupe pour concevoir et développer avec vous les plaquettes de coupe qui répondront à vos besoins.

Applications :

• Tournage • Fraisage • Perçage • Alésage • Lamage • Forage • Carottage • Ecroutage • Filetage et Taraudage

Matériaux Usinés :

• Aluminium • Aciers • Fonte • Inox • Superalliages • Titane • Matériaux durs • Carbone • Graphite • Composites • Nid d'Abeille